The food processing industry is a demanding environment. Constant operation, stringent hygiene standards, and adherence to strict regulations all place immense pressure on equipment. At the heart of many food processing machines lies the gear motor – a critical component responsible for converting electrical energy into mechanical power with precise control. Selecting the right gear motor isn’t just about getting the job done; it's about ensuring efficiency, reliability, safety, and ultimately, maintaining food safety and quality. This guide shares valuable experience-based insights into navigating the complex world of gear motor selection in this crucial industry. We'll explore common challenges, key considerations, and highlight how advanced motor technologies are impacting food processing operations – especially in light of recent trends like increased automation and the push for sustainable practices.

Gear motors are ubiquitous in food processing, powering a vast array of equipment including conveyor systems, mixers, pumps, slicers, packaging machines, and more. Their ability to provide high torque at lower speeds is particularly vital for applications requiring precise control and heavy loads. Consider the continuous operation of a dough mixer; a reliable gear motor is essential for consistency and prevents costly downtime. An example is a filling machine, needing precise positioning and speed to accurately fill containers - and this is where reliable gear motors excel.

However, food processing presents unique challenges. These include:

Choosing the right gear motor isn't a one-size-fits-all process. A thorough evaluation of application requirements is paramount. Here are some key factors:

1. Torque and Speed Requirements: This is the foundational consideration. Accurately determine the required torque and speed for the application. Oversizing or undersizing the motor will negatively impact performance and efficiency. Consider future production demands and potential upgrades.

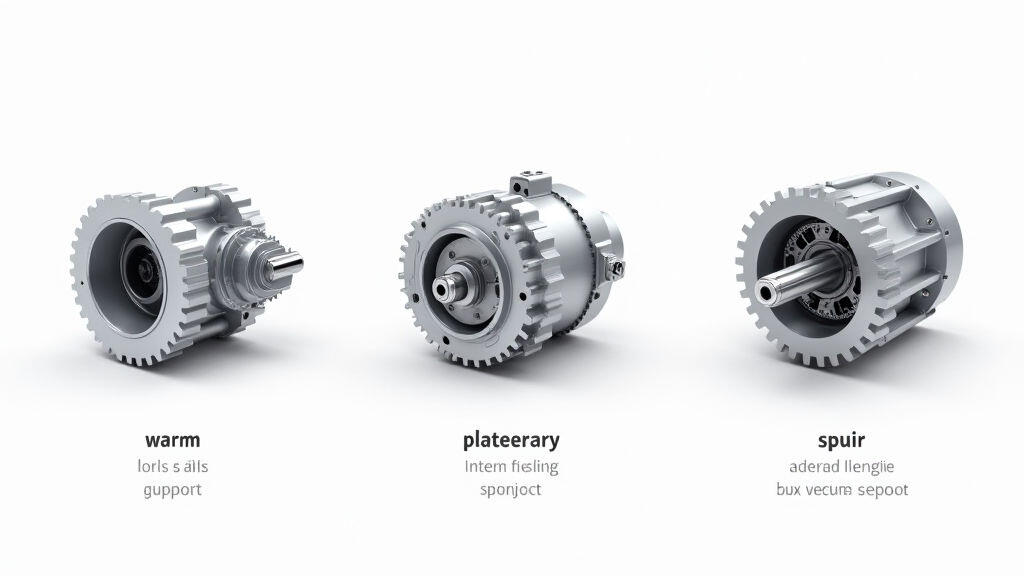

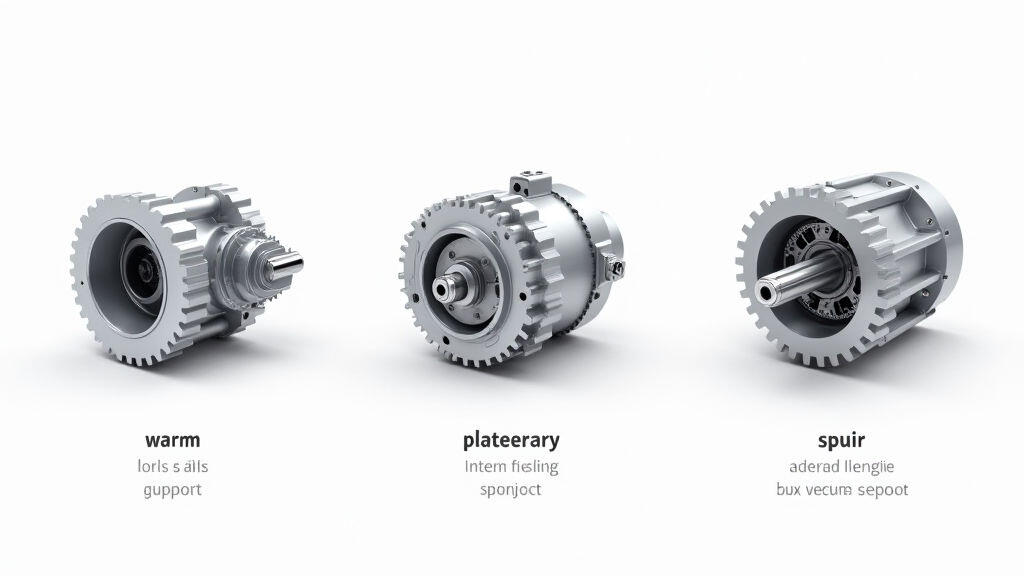

2. Gearbox Type: Different gearbox types offer varying levels of efficiency, precision, and noise.

3. Enclosure Type: Choosing the appropriate enclosure is critical for protecting the motor from the harsh food processing environment.

4. Motor Type: AC induction motors are commonly used, but brushless DC (BLDC) motors are gaining popularity due to their higher efficiency, longer lifespan, and improved controllability. Variable Frequency Drives (VFDs) are frequently employed to precisely control motor speed and torque, optimizing process efficiency.

5. Compliance and Certification: Ensure the motor meets relevant food safety regulations and certifications (e.g., FDA, NSF). Documentation and traceability are also vital.

Several prominent trends are significantly reshaping gear motor selection in the food processing industry. These trends present both challenges and opportunities:

1. Increased Automation: The push for automation is driving demand for gear motors that offer precise control, high reliability, and seamless integration with automated systems. BLDC motors and VFDs are key enablers of this trend. Motors with integrated sensors and communication capabilities (e.g., Modbus, Profibus) are becoming increasingly popular.

2. Sustainability and Energy Efficiency: Energy consumption represents a significant operational cost for food processing plants. High-efficiency gear motors, coupled with optimized motor control strategies, are crucial for reducing energy waste. Look for motors with IE3 or IE4 efficiency ratings.

3. Data-Driven Operations (IIoT): The Industrial Internet of Things (IIoT) is enabling real-time monitoring of equipment performance. Gear motors equipped with sensors can provide data on torque, speed, vibration, and temperature, allowing for predictive maintenance and optimized performance.

4. Focus on Hygiene and Clean-in-Place (CIP) Systems: Stringent hygiene requirements are fueling the demand for gear motors designed for easy cleaning and sanitation. Motors with smooth surfaces, minimal crevices, and modular designs simplify CIP procedures.

5. Remote Monitoring and Predictive Maintenance: Remote monitoring systems allow for proactive maintenance, minimizing downtime and reducing maintenance costs. Data from integrated sensors can be used to predict potential failures before they occur.

MES-Drive has been at the forefront of developing and supplying advanced gear motor solutions for the food processing industry. One particular case involved a large-scale bakery implementing an automated dough processing line. The original system relied on standard AC gear motors, resulting in frequent breakdowns, inconsistent dough mixing, and high energy consumption.

After evaluating their needs, the bakery transitioned to MES-Drive's BLDC gear motors equipped with VFDs. The benefits were immediate:

The selection of the right gear motor is a pivotal decision in the food processing industry. It’s no longer solely about meeting torque and speed requirements; it’s about incorporating considerations for hygiene, efficiency, sustainability, and data integration. As the industry continues to embrace automation, IIoT, and stringent food safety regulations, gear motors with advanced technologies like BLDC motors, VFDs, and integrated sensors will become even more critical. The move towards energy-efficient motors and predictive maintenance strategies not only reduces operational costs but also contributes to a more sustainable food processing future. Companies like MES-Drive are leading the way in providing innovative gear motor solutions that address these evolving needs, ensuring the reliability, efficiency, and safety of food processing operations in the years to come.

Leave A Reply

Your email address will not be published. Required fiels are marked